Aluminum Cans Market: Trends, Growth Drivers, and Future Outlook

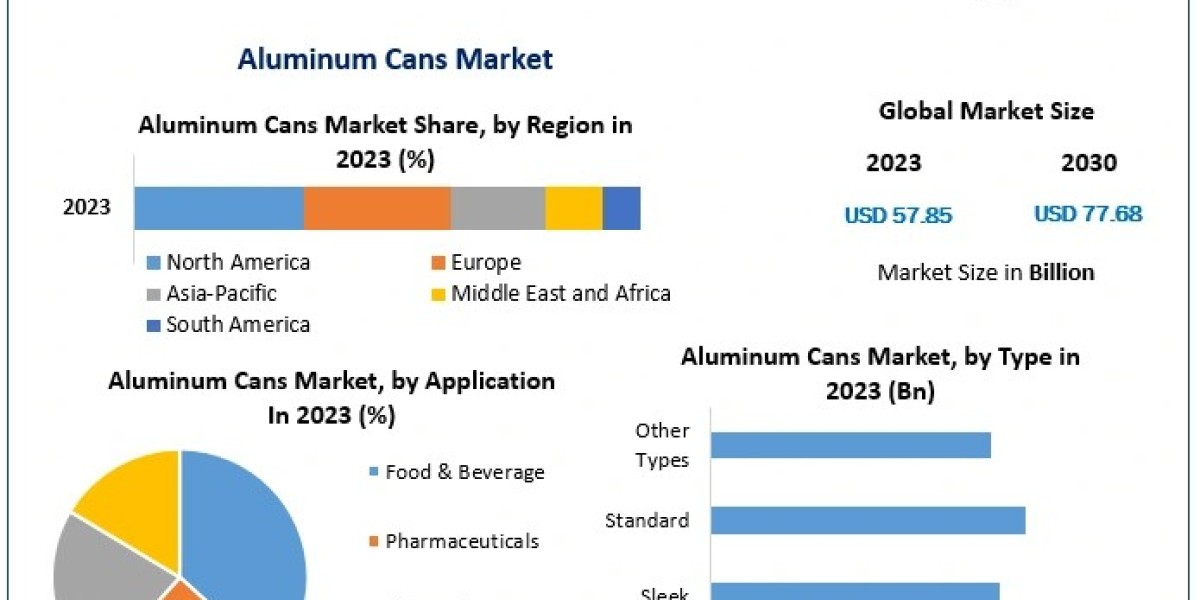

The global Aluminum Cans Market has experienced significant growth in recent years, driven by increasing environmental awareness, the expanding beverage industry, and advancements in recycling technologies. As of 2023, the market was valued at approximately USD 57.85 billion and is projected to reach USD 77.68 billion by 2030, growing at a compound annual growth rate (CAGR) of 4.3% during the forecast period.

Market Overview

Aluminum cans are widely used in packaging beverages such as soft drinks, beer, and energy drinks, as well as food products and chemicals. Their popularity stems from their durability, lightweight nature, and exceptional recyclability, making them an environmentally friendly packaging option. The ability of aluminum cans to preserve the quality and flavor of their contents has further solidified their position in the packaging industry.

Access your sample copy of this report right now: https://www.maximizemarketresearch.com/request-sample/24759/

Key Market Drivers

Environmental Sustainability: The recyclability of aluminum cans plays a pivotal role in reducing environmental impact. Unlike other packaging materials, aluminum can be recycled indefinitely without losing its properties, leading to significant energy savings and reduced greenhouse gas emissions. This aligns with global sustainability goals and has led to increased consumer and industry preference for aluminum packaging.

Growth of the Beverage Industry: The beverage sector continues to expand, with rising consumption of carbonated drinks, alcoholic beverages, and energy drinks. Aluminum cans are the preferred packaging choice in this industry due to their ability to preserve product integrity and provide convenience to consumers. The lightweight and portable nature of aluminum cans makes them ideal for on-the-go consumption.

Technological Advancements in Recycling: Advancements in recycling technologies have made aluminum can recycling more efficient and cost-effective. Enhanced collection systems and improved sorting technologies have increased recycling rates, ensuring a steady supply of recycled aluminum for can production. This not only supports environmental sustainability but also reduces production costs.

Market Challenges

Fluctuating Raw Material Prices: The aluminum market is susceptible to price volatility due to factors such as geopolitical tensions, trade policies, and supply-demand imbalances. Fluctuations in raw material prices can impact the profitability of aluminum can manufacturers and may lead to increased prices for end consumers.

Competition from Alternative Packaging Materials: Despite the advantages of aluminum cans, alternative packaging materials like plastics and glass continue to pose competition. Innovations in biodegradable plastics and lightweight glass packaging present challenges to the aluminum can market. However, the superior recyclability of aluminum often gives it an edge over these alternatives.

Energy-Intensive Production Process: The production of aluminum is energy-intensive, raising concerns about carbon emissions and environmental impact. While recycling aluminum requires significantly less energy than producing new aluminum, the initial production process remains a challenge for the industry's sustainability efforts.

Market Segmentation

The aluminum cans market can be segmented based on application, structure, and region.

By Application:

- Beverages: This segment dominates the market, with aluminum cans widely used for packaging soft drinks, alcoholic beverages, and energy drinks.

- Food: Aluminum cans are used for packaging canned foods, including soups, vegetables, and ready-to-eat meals.

- Aerosols: Products like deodorants, hairsprays, and insect repellents are often packaged in aluminum aerosol cans.

- Chemicals: Certain chemicals and industrial products are stored and transported in aluminum cans due to their durability and resistance to corrosion.

By Structure:

- 2-Piece Cans: Consist of a body and an end, commonly used for beverages due to their lightweight and cost-effectiveness.

- 3-Piece Cans: Include a body and two ends, often used for food packaging as they can withstand higher processing pressures.

Curious to peek inside? Grab your sample copy of this report now: https://www.maximizemarketresearch.com/request-sample/24759/

Regional Insights

North America and Europe have traditionally been significant markets for aluminum cans, driven by high beverage consumption and robust recycling infrastructures. However, the Asia-Pacific region is emerging as a lucrative market due to rapid urbanization, increasing disposable incomes, and a growing preference for canned beverages. Countries like China and India are witnessing substantial growth in the aluminum cans market, attributed to expanding middle-class populations and changing consumer lifestyles.

Aluminum Cans Market Competitive Landscape

1. Ball Corporation

2. Amcor

3. ORG Packaging

4. CPMC

5. Shengxing Group

6. Toyo Seikan Co., Ltd.

7. Crown

8. EXAL

9. Rexam

10. Massilly Group

11. DS container

12. TUBEX GmbH

13. Alltub Group

14. Shengya

15. Linhardt

16. Matrametal Kft.

17. James Briggs

18. CCL Container

19. Shandong Meiduo

20. Botny Chemical

21. TAKEUCHI PRESS

22. Ardagh Group

23. Silgan Holding Inc.

24. CAN-PACK SA

Stay ahead of the curve with the trending research from Maximize Market Research:

Kickboxing Equipment Market https://www.maximizemarketresearch.com/market-report/global-kickboxing-equipment-market/33406/

Body Scrub Products Market https://www.maximizemarketresearch.com/market-report/global-body-scrub-products-market/108141/

Safety Eyewear Market https://www.maximizemarketresearch.com/market-report/global-safety-eyewear-market/111306/

Connect With Us: