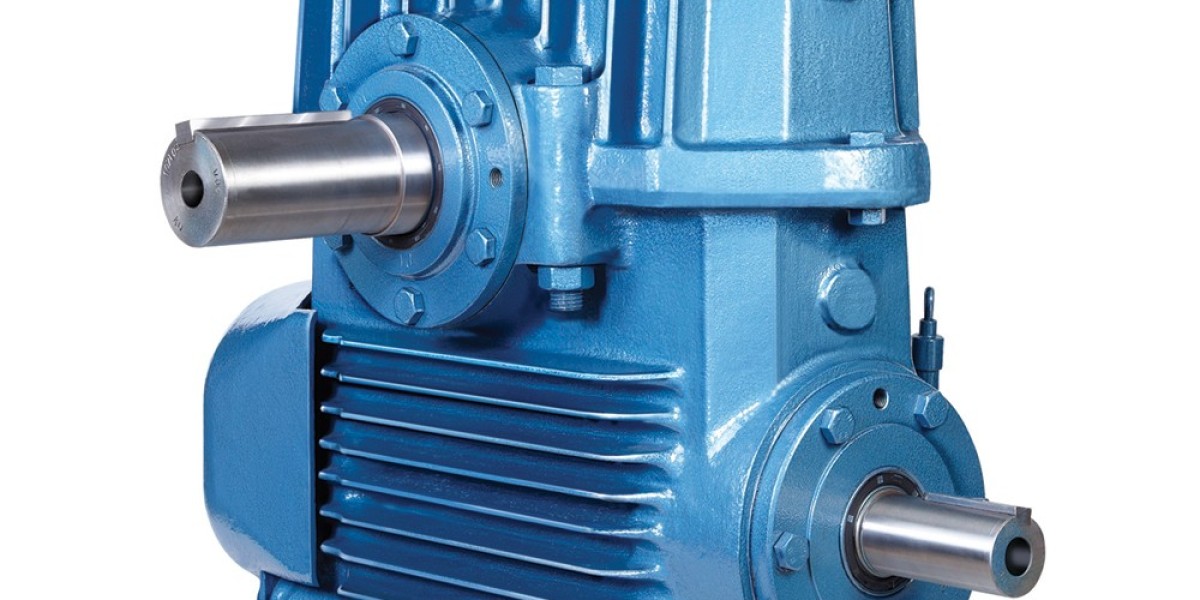

Worm gearboxes are a crucial component in various industries, providing efficient power transmission, torque multiplication, and speed reduction. Their compact design, high durability, and self-locking capabilities make them an ideal choice for diverse applications. Whether in manufacturing, construction, or automation, worm gearboxes are widely used to enhance operational efficiency.

If you’re looking for high-quality worm gearboxes, Santram Engineers is a trusted name among leading gearbox manufacturers. Explore the latest range of worm gearboxes here:

Understanding Worm Gearboxes

A worm gearbox consists of a worm (screw-like gear) and a worm wheel that work together to achieve smooth and efficient power transmission. Their unique design allows for high torque output with minimal input, making them ideal for applications that require speed reduction and load handling.

Key Benefits of Worm Gearboxes:

✔ High Torque Output – Suitable for heavy-duty applications.

✔ Compact and Space-Saving Design – Perfect for installations with limited space.

✔ Self-Locking Mechanism – Prevents back-driving, improving safety.

✔ Efficient Power Transmission – Minimizes energy loss and ensures smooth operation.

✔ Low Noise & Vibration – Ideal for noise-sensitive environments.

Top Industrial Applications of Worm Gearboxes

1. Manufacturing & Automation Industry

In manufacturing and automation, worm gearboxes are essential for conveyor systems, assembly lines, robotic arms, and industrial automation equipment. Their ability to handle heavy loads, precise motion control, and speed variation makes them perfect for these applications.

? Example: Automated conveyor belts in food processing plants use worm gearboxes for controlled speed and smooth movement of products.

2. Material Handling & Lifting Equipment

Worm gearboxes are widely used in cranes, hoists, winches, forklifts, and elevators. Their high torque output and self-locking feature prevent load slippage, ensuring safe and efficient lifting operations.

? Example: A warehouse forklift relies on a worm gearbox to control the lifting mechanism, ensuring stability while moving heavy loads.

3. Construction & Heavy Machinery

The construction industry depends on worm gearboxes for cement mixers, concrete pumps, and road construction equipment. Their rugged construction and ability to withstand harsh environments make them a reliable choice for demanding applications.

? Example: Cement mixers use worm gearboxes to control the mixing drum's rotation, ensuring consistent concrete mixing.

4. Mining & Material Processing

Mining operations require robust gearboxes that can handle heavy loads, extreme temperatures, and high dust levels. Worm gearboxes are used in conveyor belts, crushers, and ore processing machines for reliable performance under extreme conditions.

? Example: Worm gearboxes in conveyor belts help transport extracted minerals efficiently with minimal energy consumption.

5. Agriculture & Farming Equipment

In agriculture, worm gearboxes are used in irrigation systems, grain elevators, and tractor-driven implements. Their ability to provide precise control, speed reduction, and high torque makes them essential for modern farming.

? Example: A worm gearbox in an irrigation system helps regulate water flow efficiently to optimize crop watering.

6. Food & Beverage Industry

Worm gearboxes play a crucial role in the food industry, where hygiene, efficiency, and reliability are critical. They are commonly found in food processing machines, bottling plants, and packaging systems.

? Example: Worm gearboxes in food packaging machines ensure accurate positioning of labels and sealing of food products.

7. Pharmaceutical & Chemical Processing

Precision and hygiene are paramount in the pharmaceutical and chemical industries. Worm gearboxes are used in tablet pressing machines, mixing equipment, and chemical dosing pumps to maintain accurate and consistent production processes.

? Example: A pharmaceutical tablet press machine uses a worm gearbox for controlled pressure application during tablet formation.

8. Renewable Energy (Wind & Solar Power Systems)

Worm gearboxes are used in solar tracking systems and wind turbines to optimize energy generation. Their high efficiency and durability make them a preferred choice for green energy solutions.

? Example: Solar panel tracking systems use worm gearboxes to adjust panel angles for maximum sunlight absorption throughout the day.

9. Textile Industry

In textile manufacturing, worm gearboxes are used in spinning, weaving, and dyeing machines. Their ability to provide smooth motion, high torque, and minimal maintenance ensures uninterrupted production.

? Example: A textile loom machine uses a worm gearbox to control fabric tension and movement.

10. Water & Wastewater Treatment Plants

Worm gearboxes are essential in pumps, agitators, and filtration systems used in water treatment plants. They help regulate flow rates and ensure efficient water purification and distribution.

? Example: A sludge dewatering machine in a wastewater treatment plant relies on a worm gearbox for consistent rotation of the screw press mechanism.

Choosing the Right Worm Gearbox

Selecting the right worm gearbox depends on several factors, including:

✔ Load Capacity: Choose a gearbox with sufficient torque to handle your application.

✔ Speed Reduction Ratio: Ensure it meets your speed control requirements.

✔ Material & Coating: Look for corrosion-resistant materials for longer durability.

✔ Mounting & Space Constraints: Choose a compact design if space is limited.

✔ Lubrication & Maintenance: Opt for low-maintenance gearboxes to reduce downtime.

Why Choose Santram Engineers for Worm Gearboxes?

As a leading name among gearbox manufacturers, Santram Engineers offers high-quality worm gearboxes designed for maximum durability, efficiency, and performance. Their products are trusted across various industries, ensuring smooth and reliable power transmission.

Final Thoughts

Worm gearboxes are indispensable in various industries, ensuring efficient motion control, power transmission, and load management. Whether used in manufacturing, construction, mining, or renewable energy, their durability, compact design, and high torque output make them a preferred choice for industrial applications.

Looking for the best worm gearboxes for your business? Santram Engineers provides premium gear solutions tailored to your industry needs. Contact them today for expert advice and top-quality gearbox solutions!