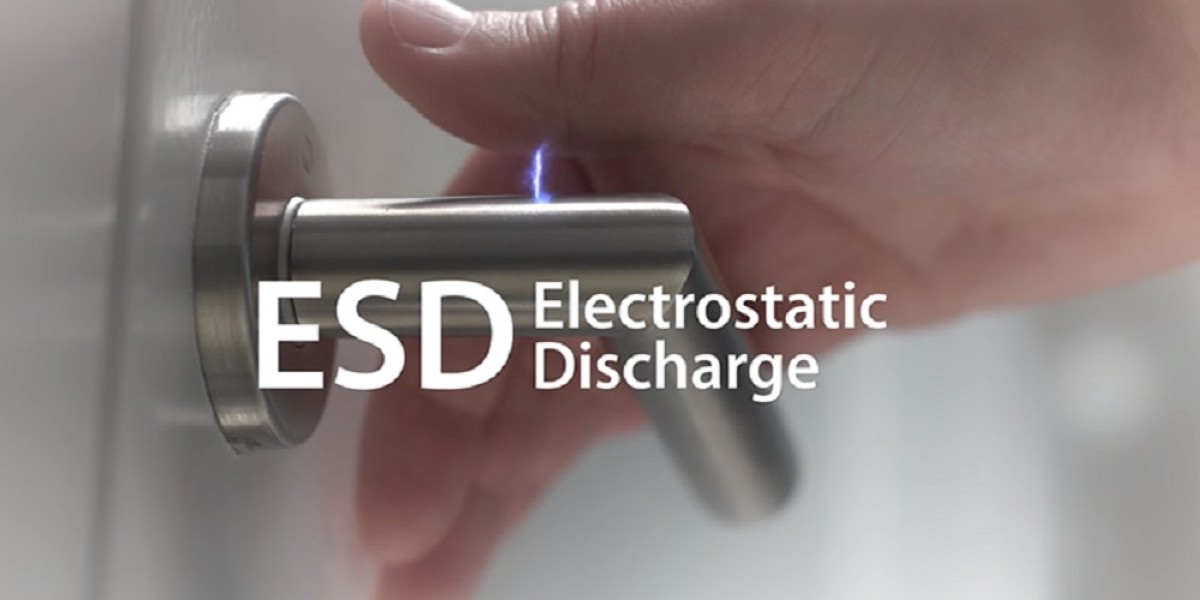

Introduction

The Electrostatic Discharge packaging market is evolving rapidly, driven by technological advancements, growing demand for consumer electronics, and stringent industry regulations. As the need for effective electrostatic protection increases across industries such as automotive, aerospace, healthcare, and semiconductors, companies are investing in innovative packaging solutions. This article explores emerging technologies and business strategies shaping the future of the ESD packaging market.

Emerging Technologies in ESD Packaging

1. Smart Packaging with IoT Integration

The integration of Internet of Things (IoT) technology in ESD packaging is revolutionizing the industry. Advanced ESD packaging solutions now feature embedded sensors and RFID tags that monitor electrostatic conditions, temperature, and humidity in real time. These smart solutions help prevent damage to sensitive electronic components during storage and transit, improving traceability and supply chain efficiency.

2. Sustainable and Eco-Friendly Materials

Environmental concerns and stringent regulations are driving the development of sustainable ESD packaging. Companies are focusing on recyclable and biodegradable materials, such as bio-based polymers, conductive paper, and reusable shielding bags. These eco-friendly alternatives reduce waste and carbon footprints while maintaining effective electrostatic protection.

3. Conductive and Dissipative Nanomaterials

Advancements in nanotechnology are enabling the development of high-performance ESD packaging. Conductive and dissipative nanomaterials, such as carbon nanotubes and graphene, are being incorporated into packaging materials to enhance electrostatic protection without adding significant weight or cost.

4. Customizable and Modular Packaging Solutions

To address the unique needs of various industries, manufacturers are developing modular and customizable ESD packaging solutions. These include adjustable storage bins, foam inserts, and tailored protective casings that provide maximum flexibility and cost-efficiency.

5. AI-Driven Quality Control in Manufacturing

Artificial Intelligence (AI) and machine learning are playing a crucial role in quality assurance within ESD packaging production. AI-powered inspection systems detect defects in packaging materials, ensuring consistency and reliability while reducing manufacturing waste and operational costs.

Business Strategies Driving Market Growth

1. Strategic Partnerships and Collaborations

Companies in the ESD packaging sector are increasingly forming strategic alliances to enhance their market presence and expand their product portfolios. Collaborations between packaging manufacturers and semiconductor firms are leading to the development of industry-specific solutions that improve the efficiency of supply chains.

2. Expansion into Emerging Markets

With growing industrialization in emerging economies, key market players are expanding their operations in regions such as Asia-Pacific, Latin America, and the Middle East. Establishing local manufacturing units and distribution networks in these high-growth markets helps companies reduce costs and cater to rising demand.

3. Investment in Research and Development (R&D)

Continuous investment in R&D is essential for staying competitive in the ESD packaging industry. Companies are focusing on the development of next-generation materials and advanced protective solutions that offer better performance, durability, and cost-effectiveness.

4. Adoption of Digital Transformation in Supply Chains

The digitalization of supply chains is helping companies improve operational efficiency and reduce lead times. Advanced tracking systems, AI-driven logistics planning, and automation in inventory management are enabling businesses to optimize their ESD packaging processes.

5. Compliance with Global Regulatory Standards

Adhering to international ESD protection standards, such as ANSI/ESD S20.20 and IEC 61340-5-1, is crucial for companies aiming to establish a strong market presence. Compliance ensures product reliability, builds customer trust, and opens opportunities for global trade.

Market Dynamics

Market Drivers

Growing Demand for Consumer Electronics and Semiconductors – The rise in AI, 5G, and IoT-based devices is fueling the need for reliable ESD packaging solutions.

Expansion of Electric Vehicle (EV) Production – The increasing use of electronic components in EVs and autonomous vehicles has heightened the need for advanced ESD protective packaging.

Rising Awareness of Product Safety – Businesses are prioritizing electrostatic discharge protection to prevent costly damages to sensitive electronic devices.

Regulatory Pressure and Industry Compliance – Stringent regulations and global standards are pushing companies to adopt high-quality ESD packaging solutions.

Growth in E-Commerce and Global Logistics – The surge in online electronics sales has increased the need for secure and durable ESD packaging.

Challenges and Restraints

High Production Costs – The use of specialized materials and advanced manufacturing technologies makes ESD packaging more expensive.

Lack of Standardization in Emerging Markets – Inconsistent regulatory frameworks in some regions can slow market adoption.

Environmental Concerns Regarding Non-Recyclable Materials – Companies must invest in sustainable alternatives to reduce their environmental impact.

Regional Market Outlook

North America

The North American ESD packaging market is driven by strong demand from the semiconductor, aerospace, and IT industries. The region has a well-established regulatory framework and a high level of technological adoption, making it a key market for innovation in ESD packaging.

Europe

Europe is witnessing steady growth due to increasing investments in electric vehicle production and medical electronics. Leading countries such as Germany, France, and the UK are at the forefront of sustainable packaging solutions and advanced materials research.

Asia-Pacific

Asia-Pacific is the fastest-growing region, supported by rapid industrialization, the booming consumer electronics market, and the presence of major semiconductor manufacturers in countries such as China, Japan, South Korea, and India.

Latin America & Middle East and Africa

These regions are gradually expanding in the ESD packaging sector due to increasing investments in the automotive and electronics industries. Businesses are focusing on improving product safety and regulatory compliance to capture market opportunities.

Market Forecast (2024-2030)

The global ESD packaging market is projected to grow at a CAGR of 6-8% from 2024 to 2030, reaching a valuation of over USD 10 billion. Key growth drivers include rising demand for smart packaging, sustainability initiatives, and the expansion of digital supply chain solutions. The industry is expected to witness significant innovation in materials, technology integration, and regulatory compliance.

Conclusion

The Electrostatic Discharge packaging market is undergoing a transformation fueled by emerging technologies and strategic business initiatives. Companies investing in smart, sustainable, and high-performance packaging solutions will gain a competitive advantage. With continued advancements in IoT-enabled tracking, AI-driven manufacturing, and eco-friendly materials, the industry is set to experience strong growth in the coming years. Businesses that adapt to market trends and evolving regulations will be well-positioned for success in the dynamic ESD packaging landscape.