The vapour recovery units market is expected to experience continued growth due to increasing environmental concerns and the adoption of stricter emission standards. However, several challenges could impact the growth and adoption of vapour recovery units (VRUs) in the coming years. Despite their potential to reduce harmful emissions, the market faces significant threats that could hinder development, increase costs, and limit their widespread adoption. In 2025 and beyond, these challenges need to be addressed to ensure the long-term success and profitability of VRUs.

High Initial Investment Costs

One of the primary threats to the vapour recovery units market is the high initial investment required for installing VRUs. These systems are complex and often require a substantial capital investment, which can be a significant barrier for small and medium-sized enterprises (SMEs) or businesses in developing regions. The upfront costs include the installation of the units, as well as the required infrastructure upgrades and specialized labor. Although these systems offer long-term savings and benefits, the high initial capital expenditure can discourage companies from adopting them.

Maintenance and Operational Costs

Another significant challenge for the vapour recovery units market is the ongoing maintenance and operational costs associated with the systems. While VRUs help reduce emissions and enhance energy efficiency, they also require regular maintenance, monitoring, and repairs. In industries where VRUs operate under harsh conditions, such as oil and gas or petrochemicals, these systems may experience wear and tear, leading to higher operational costs. Additionally, spare parts and technical expertise may be expensive, further adding to the financial burden of maintaining VRUs. These costs can be a deterrent for companies looking for low-cost solutions.

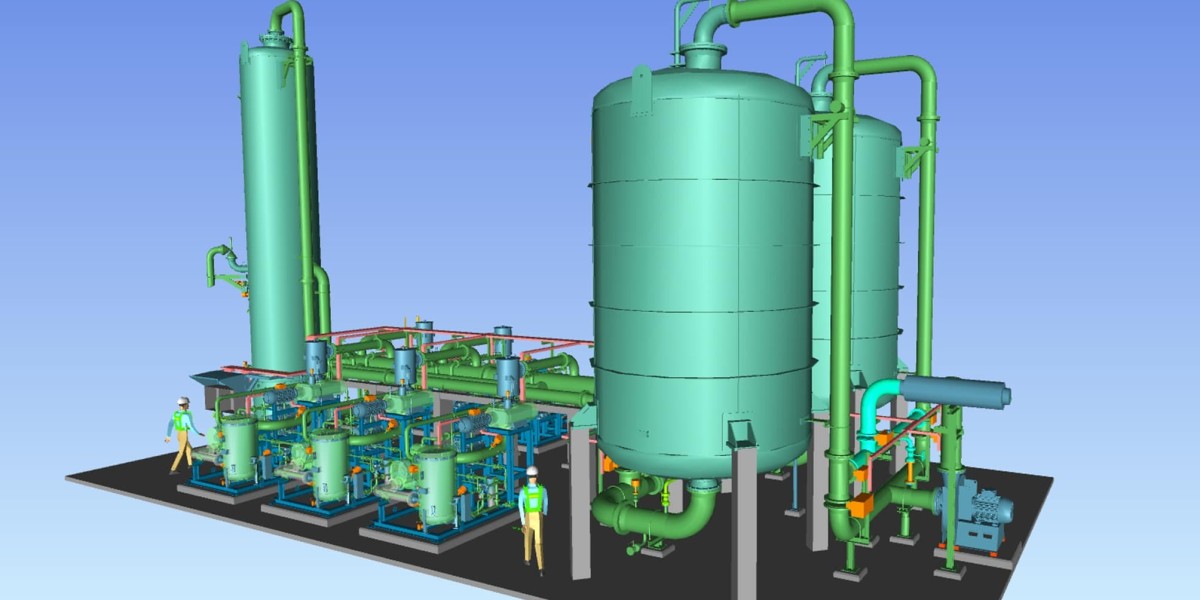

Technological Complexity and Integration Issues

Vapour recovery units are technologically advanced systems that require skilled professionals for installation and operation. The complexity of integrating VRUs into existing industrial infrastructure can be a major challenge, especially for older plants or facilities. The integration of new technologies often requires significant adjustments to existing processes, and failure to properly implement VRUs can lead to inefficiencies or even system failures. The lack of standardization in the design and installation of VRUs also contributes to the difficulty of ensuring compatibility across different industrial setups, making the integration process more challenging.

Regulatory Variations Across Regions

While global environmental regulations are becoming more stringent, regulatory requirements for vapour recovery units can vary significantly across regions. In some countries, regulations may be unclear or lack enforcement, creating uncertainty in the market. Companies may face difficulties in determining the most cost-effective and compliant VRU solution if local regulations are not clearly defined. Furthermore, the evolving nature of environmental regulations means that companies will need to stay up-to-date with new standards, which could lead to additional costs for compliance. This lack of uniformity across regions can make it difficult for businesses to adopt VRUs, particularly in markets with weaker environmental laws.

Limited Awareness and Adoption in Emerging Markets

In many emerging markets, there is still limited awareness of the benefits of vapour recovery units and the importance of reducing industrial emissions. In these regions, industries may prioritize cost-cutting measures over environmental sustainability, which can limit the adoption of VRUs. Additionally, emerging markets often face economic challenges, including budget constraints and limited access to advanced technology, which makes it difficult for companies to invest in vapour recovery systems. This results in slower adoption rates of VRUs in these regions, despite their long-term environmental and economic advantages.

Competition from Alternative Technologies

Another threat to the vapour recovery units market is the increasing competition from alternative technologies designed to reduce emissions. Technologies such as carbon capture and storage (CCS), advanced filtration systems, and cleaner fuel alternatives are emerging as potential competitors to VRUs. While VRUs are highly effective in capturing volatile organic compounds (VOCs) and other harmful gases, alternative technologies may offer more cost-effective or efficient solutions in certain applications. As industries look for new ways to meet environmental standards, the adoption of alternative technologies could slow down the growth of the VRU market.

Economic Slowdowns and Market Uncertainties

Economic downturns and global market uncertainties pose another risk to the vapour recovery units market. In times of economic recession, companies may prioritize short-term cost-saving measures over long-term environmental investments, leading to a decline in the adoption of VRUs. Industries that are already facing financial constraints may be less willing to invest in the installation of costly vapour recovery systems, particularly when the return on investment is perceived to be long-term. Economic instability and unpredictable market conditions can also delay infrastructure projects, including the installation of VRUs, which could ultimately impact the market growth.

Lack of Skilled Workforce

As vapour recovery units are complex systems requiring specialized knowledge, the lack of a skilled workforce can be a significant challenge for the market. Industries that adopt VRUs often struggle to find trained professionals capable of managing the installation, operation, and maintenance of these systems. The need for highly skilled engineers and technicians is critical, and a shortage of qualified personnel can delay projects, increase operational risks, and lead to inefficient system operation. The lack of education and training programs focused on VRU technologies can exacerbate this issue, hindering market growth.