The vacuum deaerators market is undergoing continuous innovation to meet the evolving demands of various industries, including power generation, pharmaceuticals, and food processing. These innovations are driven by the increasing need for energy efficiency, environmental sustainability, and system reliability. New technologies are emerging to improve the overall efficiency of vacuum deaerators, making them more cost-effective and accessible to a broader range of industries. As these advancements progress, vacuum deaerators are becoming a crucial component in industries focused on minimizing corrosion, enhancing fluid quality, and optimizing energy consumption.

Introduction of Smart and Automated Deaeration Systems

The integration of smart technologies and automation in vacuum deaerators has revolutionized the market. Advanced sensors and control systems now monitor parameters such as dissolved oxygen levels, pressure, and temperature in real-time. These systems ensure precise control, reducing human intervention and increasing operational efficiency. Automation also allows for remote monitoring and management, enabling operators to make adjustments as needed without being physically present. This innovation is expected to become more widespread, with forecasted growth in the adoption of smart deaeration systems by 2025.

Energy-Efficient Solutions

As industries globally continue to focus on sustainability, vacuum deaerators are becoming more energy-efficient. Innovations in vacuum technology, such as multi-stage systems and optimized vacuum pumps, are reducing energy consumption while maintaining the same level of performance. These energy-efficient solutions are particularly beneficial for industries like power plants, where the cost of energy plays a significant role in overall operational expenses. With the increasing emphasis on reducing carbon footprints, vacuum deaerators designed for low energy consumption are likely to dominate the market in the coming years.

Enhanced Materials for Corrosion Resistance

Another key innovation in the vacuum deaerators market is the development of advanced materials that enhance the corrosion resistance of the system components. In industries such as power generation, where the deaeration process is essential for protecting boilers and turbines from corrosion, the use of advanced coatings and corrosion-resistant alloys is becoming more prevalent. These materials extend the lifespan of vacuum deaerators, reducing maintenance costs and improving overall system reliability.

Integration with Renewable Energy Systems

The integration of vacuum deaerators with renewable energy systems is an emerging trend, particularly in industries seeking to reduce their environmental impact. Solar, wind, and other renewable energy sources are increasingly being used to power vacuum deaerators, reducing reliance on traditional energy grids. This innovation is aligned with the growing demand for sustainable practices, particularly in regions with strong commitments to renewable energy adoption. By utilizing renewable energy, industries can further reduce the carbon footprint associated with their operations.

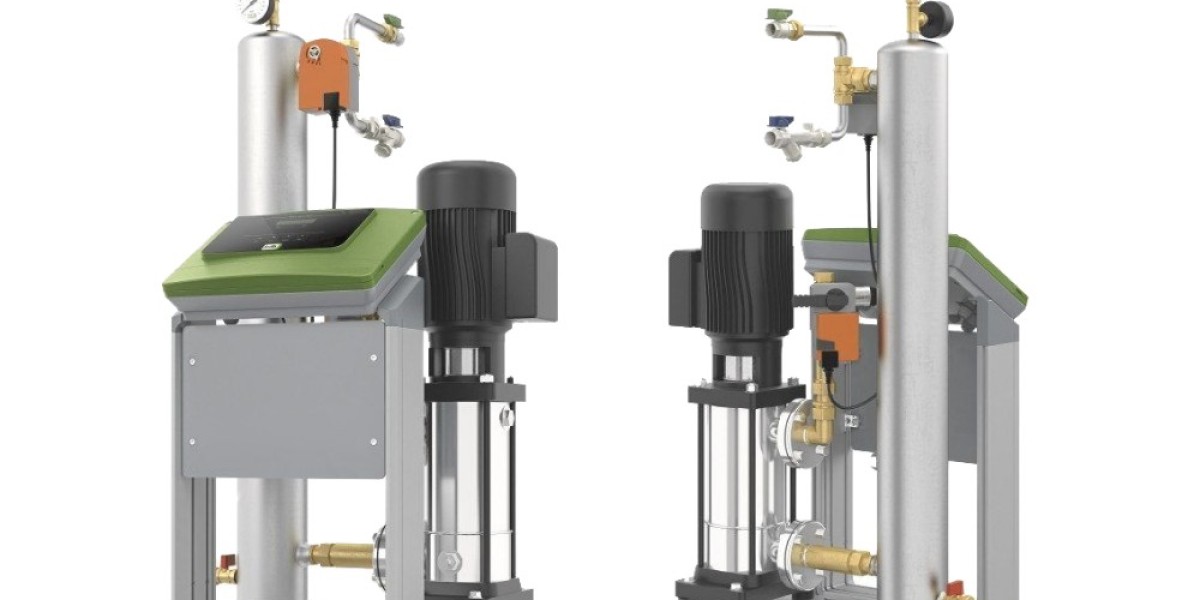

Development of Compact and Modular Systems

Vacuum deaerators are also becoming more compact and modular, allowing them to be easily integrated into smaller facilities or systems with limited space. This innovation is especially relevant for industries such as pharmaceuticals and food processing, where space constraints are common. Compact and modular systems can be customized based on the specific needs of the facility, providing a more flexible and scalable solution. These systems are expected to gain traction in 2025 and beyond, as they offer a versatile solution for industries with space limitations.

Digitalization and Data Analytics

The role of data analytics and digitalization in the vacuum deaerators market cannot be overlooked. By collecting and analyzing data from deaeration systems, industries can predict maintenance needs, identify potential issues before they become problems, and optimize the overall performance of the system. Digitalization also facilitates better decision-making by providing actionable insights into the operational efficiency of vacuum deaerators. As the industry embraces digital transformation, this trend is expected to drive further innovation in vacuum deaerators by 2025.

Adoption of Environmentally Friendly Deaeration Technologies

As part of the broader push for sustainability, vacuum deaerators are incorporating more environmentally friendly technologies. These innovations aim to reduce the environmental impact of the deaeration process, such as using water-efficient systems or reducing chemical usage in water treatment. In particular, industries that deal with large volumes of water, such as power generation and manufacturing, are increasingly adopting these greener technologies to meet both regulatory standards and consumer expectations for environmentally responsible practices.

Customization for Specific Industrial Needs

Another significant innovation in the vacuum deaerators market is the increased customization of systems to meet the specific needs of different industries. For example, in the pharmaceutical industry, vacuum deaerators must meet stricter hygiene and purity standards. This has led to the development of specialized systems designed for high-purity applications. Similarly, the food and beverage industry requires deaerators that can handle liquids like beer or soda, where oxygen removal is crucial for product quality and shelf life. Customized solutions are expected to become more prevalent as industries demand more specialized equipment.

Advanced Monitoring and Diagnostic Tools

New monitoring and diagnostic tools are being incorporated into vacuum deaerators to detect issues such as gas leakage or system inefficiencies. These tools provide real-time feedback to operators, allowing for quick troubleshooting and repairs. By preventing breakdowns and reducing downtime, these innovations contribute to improved reliability and productivity. The adoption of advanced monitoring systems is expected to increase, particularly in critical industries like power generation and pharmaceuticals, where system failures can lead to significant financial losses.

Increased Focus on Lifecycle Management

Vacuum deaerators are now being designed with a greater focus on lifecycle management. Innovations in design, materials, and maintenance strategies are making it easier for companies to extend the operational life of their systems. Additionally, manufacturers are offering lifecycle services, such as predictive maintenance and end-of-life management, to help customers maximize the value of their investment. This trend is expected to grow as industries recognize the long-term benefits of maintaining and upgrading their deaeration systems.