Introduction

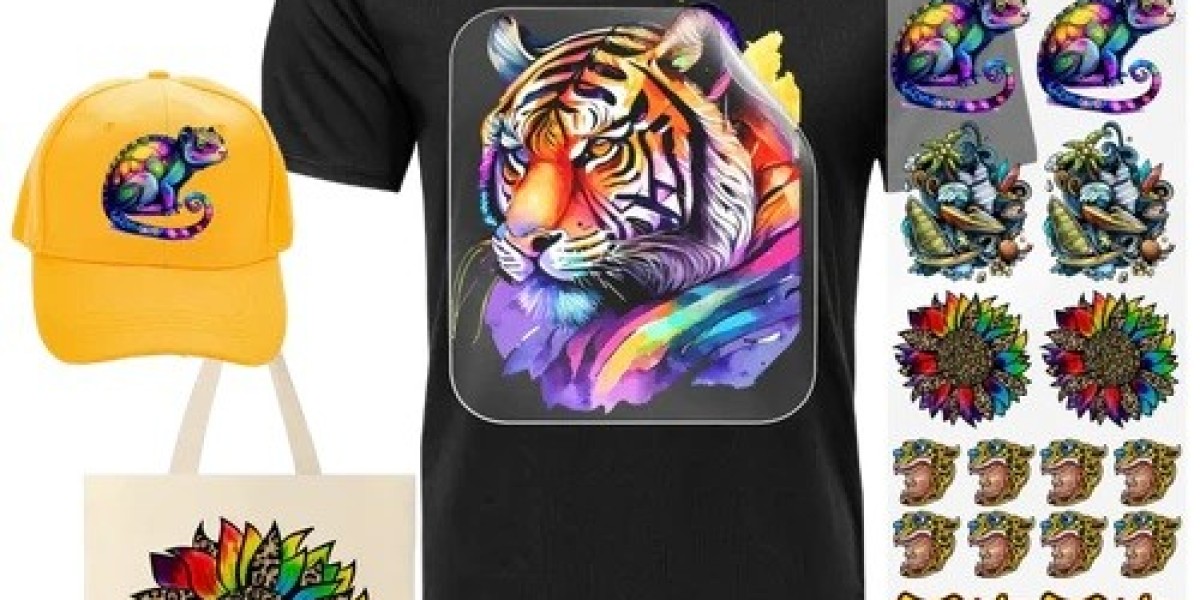

Custom printing has taken a significant leap forward with DTF transfers (Direct to Film). This innovative method is rapidly replacing traditional heat transfer and screen-printing techniques due to its high-quality prints, versatility, and cost-effectiveness. Whether you are a printing business owner or a DIY enthusiast, understanding DTF transfers can help you create vibrant and durable designs for various fabrics and materials.

What Are DTF Transfers?

DTF transfers involve printing a design onto a special film, which is then transferred to a garment using heat and pressure. Unlike direct-to-garment (DTG) printing, which applies ink directly to fabric, DTF printing allows designs to be printed separately and applied later, making it an ideal choice for bulk orders, on-demand prints, and intricate designs.

How DTF Transfers Work

The process of creating DTF transfers involves several steps:

Design Creation – The desired artwork is created using graphic design software such as Adobe Photoshop or CorelDRAW.

Printing the Design – A specialized DTF printer prints the design onto a PET film using water-based pigment inks.

Applying Adhesive Powder – A fine layer of hot-melt adhesive powder is sprinkled over the printed design, ensuring proper adhesion to the fabric.

Curing the Transfer – The film is heated to cure the adhesive, allowing it to bond well with fabric when pressed.

Heat Press Transfer – The cured film is placed on the garment and transferred using a heat press machine at around 300-350°F (150-180°C).

Peeling the Film – After pressing, the film is peeled off, leaving behind a durable, vibrant design.

Benefits of DTF Transfers

1. Versatility

DTF transfers work on a wide range of fabrics, including cotton, polyester, blends, denim, leather, and even non-textile surfaces. This flexibility makes it a preferred choice for custom apparel businesses.

2. High Durability

Unlike traditional heat transfers, DTF transfers are highly durable and resistant to cracking, peeling, and fading. They withstand multiple washes while maintaining their vibrancy.

3. Cost-Effective

With DTF transfers, there is minimal material waste, and no need for expensive pre-treatment processes required in DTG printing. This makes it a more affordable option for businesses and hobbyists alike.

4. Vibrant and Detailed Prints

DTF printing produces rich, high-resolution prints with excellent color accuracy. It allows for intricate details and full-color designs without compromising quality.

5. No Weeding Required

Unlike vinyl heat transfer, where excess material must be removed (weeded) manually, DTF transfers eliminate this tedious step, saving time and effort.

DTF vs. Other Printing Methods

| Feature | DTF Transfers | DTG Printing | Screen Printing | Vinyl Heat Transfer |

|---|---|---|---|---|

| Fabric Compatibility | Cotton, Polyester, Blends, Denim, Leather | Cotton Only | Limited | Cotton, Polyester |

| Durability | High | Medium | High | Medium |

| Cost | Affordable | Expensive | High Setup Cost | Affordable |

| Print Quality | High | High | High | Medium |

| Ease of Use | Easy | Moderate | Difficult | Moderate |

How to Start with DTF Transfers

If you’re interested in incorporating DTF transfers into your business or personal projects, here’s how to get started:

1. Get the Right Equipment

DTF Printer – A high-quality printer designed for DTF printing.

PET Film – Special transfer film used for printing designs.

DTF Ink – Water-based pigment inks that provide vibrant prints.

Adhesive Powder – Ensures strong bonding between the film and fabric.

Heat Press Machine – Transfers the design onto the fabric with heat and pressure.

2. Choose the Right Software

Design software like Adobe Illustrator, CorelDRAW, or Procreate can help create detailed and customized artwork for DTF transfers.

3. Practice and Experiment

Before applying prints to high-value garments, practice on test fabrics to understand temperature settings, pressure, and peeling techniques.

Common Mistakes to Avoid

Incorrect Temperature and Pressure – Using the wrong heat press settings can result in weak adhesion or damage to the print.

Poor Design Preparation – Low-resolution images lead to pixelated or blurry prints.

Skipping the Adhesive Powder – Without adhesive powder, the design won’t stick properly to the fabric.

Not Curing the Print Properly – Inadequate curing results in prints that peel off after washing.

FAQs About DTF Transfers

1. Are DTF transfers better than sublimation?

DTF transfers work on various fabrics, unlike sublimation, which requires polyester-based materials. Additionally, DTF prints don’t fade over time like sublimation prints.

2. Can I wash garments with DTF prints?

Yes! DTF prints are highly durable and can withstand multiple washes without fading or peeling. Always follow care instructions like washing in cold water and avoiding harsh detergents.

3. Do I need a special printer for DTF transfers?

Yes, a dedicated DTF printer is required. Converting a standard inkjet printer for DTF is possible but not recommended for professional results.

4. Can I use DTF transfers on dark fabrics?

Absolutely! Unlike some printing methods that require light-colored garments, DTF transfers produce vibrant prints on both light and dark fabrics.

5. Is DTF printing eco-friendly?

DTF printing uses water-based inks and produces minimal waste, making it a more sustainable printing option compared to other methods.

Conclusion

DTF transfers have revolutionized the custom printing industry by offering high-quality, durable, and versatile designs at an affordable cost. Whether you’re starting a printing business or want to create custom apparel for personal use, DTF transfers provide an excellent solution for vibrant, long-lasting prints. By following the right techniques and investing in quality equipment, you can achieve professional-grade results with ease.